No energy transition without traction batteries from Europe

(© Kalyakan – stock.adobe.com)

No energy transition without traction batteries from Europe

The energy transition requires a paradigm shift in power supply: storage capacities for green electricity must be massively expanded. Electric car batteries can contribute to electric grid stability. They are particularly sustainable if the batteries are produced in Europe.

CO2 emissions are clearly too high: road transportation must deliver so that EU climate targets are not jeopardized

2024/03/15 - The figures are a fiasco for European transportation policy: in 2019, road transportation was responsible for 26 percent of all CO2 emissions in the EU. In 1990, its share was “only” 15 percent. However, while other sectors have significantly stepped up the pace and total CO2 emissions have fallen by 23 percent since 1990, emissions generated by road transportation have increased by 21 percent over the same period.

The electrification of passenger and commercial vehicles is the order of the day to ensure that the EU’s climate targets do not fail due to road transportation – after all, Europe aims to become carbon neutral by 2050 and reduce greenhouse gas emissions by at least 55 percent by 2030 compared to 1990 levels. In addition to new rules for emissions trading in the transport sector, the EU Commission is proposing stricter CO2 emission standards for cars and light commercial vehicles. This could accelerate the transition to greenhouse gas-free mobility. Manufacturers are to meet more demanding and stringent CO2 fleet limits as of 2030 and newly registered vehicles are required to be emission-free as of 2035.

Traction batteries for electric cars: A gigantic future market

The political course has been charted – and is creating a gigantic future market. After all, every newly registered electric car needs a traction battery. While the annual production capacity for such batteries in Europe totaled around 44 GWh in 2020, this is set to be ramped up to 1,200 GWh by the end of the decade. The expansion is necessary to meet the demand for battery cells for European electric cars from local production in the future. This is not currently the case: European electric car manufacturers currently mainly source their batteries from China, South Korea or Japan. As the battery makes up around 30 to 40 percent of the added value of an electric car, this is not good news for Europe as a business location.

“Local for local” strategy ensures independence from global supply chains

In recent years, manufacturers have also had bad experiences with dependence on global supply chains. Because of this, an increasing number of companies is adopting the “Local for local” production and sourcing strategy. This simplifies logistics and reduces the risk of production downtime or supply bottlenecks to an acceptable level. The establishment and expansion of a European battery ecosystem is worth more than 67 billion euros of investment to the industry by 2030. According to a research team from Münster/Westphalia University of Münster, at least 20 “gigafactories” are needed in Europe – a quarter of the global production capacity. It is planned that Germany will account for more than a third of European battery production.

Energy storage: Important for grid stability with more green electricity

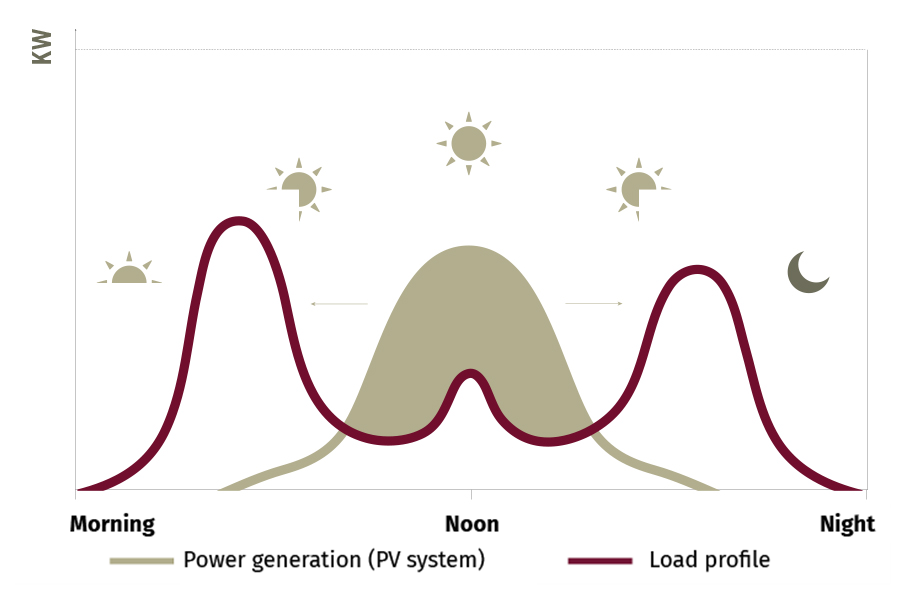

Energy storage systems have a special and vital role to play in the energy transition: while in the past they mainly ensured the power supply in the event of power outages or provided electricity where there were no power lines, in the future they will form the decentralized backbone of grid stability – and thus a secure and crisis-proof electricity supply . The electricity generated in Europe is becoming greener every year – which is also absolutely crucial for a carbon neutral energy transition. In 2010, the share of renewable energies in electricity consumption was still around 20 percent – ten years later, it was already just under 40 percent. By 2030, it is expected to rise to 55 percent, and by 2050 to as much as 88 percent. However, due to the time of day and the weather conditions, wind and solar power plants do not feed green electricity constantly or evenly into the grid. Even today, photovoltaic and wind power plants are repeatedly switched off for safety reasons because the grids can no longer store the electricity being generated. Conversely, gas or coal-fired power plants must provide the necessary base load when electricity is needed but too little is being fed into the grid by solar panels and wind turbines.

Energy storage systems can ensure the power supply and grid stability during “dark doldrums”. According to the sustainability scenario of the IEA (International Energy Agency), a global energy storage capacity of almost 10,000 GWh in the form of batteries and other storage systems will be required by 2040 in order for the world to meet its climate protection and sustainability targets – nearly 50 times the current figure. The European Association for Storage of Energy (EASE) estimates that at least 14 GW/year of new energy storage capacity will be needed in the EU by 2030, compared to the 0.8 GW/year of new capacity installed in 2020 according to the IEA – this is an eighteen-fold increase in the speed of creating new energy storage capacity.

Electric cars and the energy transition: Going hand in hand

This is where the traction batteries for electric vehicles come into play. While the enormous power requirements of a highly electrified fleet used to pose a problem for a green energy mix, the picture has changed: the enormous storage capacities of current electric cars – between 25 and 50 kWh – can substantially contribute to the energy transition if they don’t just draw power from the grid, but also return it when needed. RWTH Aachen University estimates that over 650,000 stationary battery storage systems (e.g., for private photovoltaic systems) with a storage capacity of 7.0 GWh were in operation in Germany at the end of 2022. However, there were also 1,878,000 electric vehicles with a total battery capacity of 65 GWh. The cumulated battery capacity of around 72 GWh was therefore almost twice as high as the 39 GWh of all pumped-storage power plants installed in Germany. In other words: already today, electric cars could potentially contribute more to grid stability than existing storage structures. Another plus: the number of electric vehicles is growing strongly from year to year.

Thanks to intelligent connectivity, they don’t even have to become “stationary vehicles”. This is because a single-family household with a family of four only consumes around eight kWh a day: energy demand that could be met for almost a full week with the electricity from the traction battery of an electric car. However, the electric car in the carport or garage would not need to serve as the basic supplier: its only task would be to balance out the peaks in electricity production and demand.

A decentralized power grid is still a dream of the future. This would require electric cars that are designed for bidirectional charging, as well as wallbox charging stations – but above all: more batteries. It would also be ideal if the energy storage units came from the factories that are currently being built all over Europe.

Batteries from Europe make electric cars cheaper: Thanks to a smaller carbon footprint

In addition to being less dependent on global supply chains, car manufacturers prefer local battery production for another reason. Whether in their own plant or purchased from a supplier: a strong argument in favor of a traction battery will increasingly be the carbon footprint of its production. High levels of CO2 emissions in battery production and transport impede the efforts of vehicle manufacturers to achieve their own climate neutrality targets – and are also quite costly. This is because CO2 certificates are to be traded freely on the market starting in 2027 – as in the original European emissions trading scheme. Free emission rights, on the other hand, are not planned.

In addition to short transport routes for the batteries, which cannot be transported around the globe as easily as computer chips, the European energy mix also speaks in favor of the location. The WWU research team in Münster estimates that a “gigafactory” would require 1,000 GWh of electricity per year. With a 55 percent projected share of green electricity by 2030, the carbon footprint of batteries “made in Europe” would be significantly smaller than the carbon footprints of batteries from other regions. China lags far behind in comparison. By the end of 2023, the share of non-fossil energy sources in Chinese electricity production (including nuclear power) will be around 18 percent, as announced by the National Energy Agency (NEA) in April 2023. China will not reach its peak in terms of coal-fired power generation until 2030.

This is why SVOLT and other battery manufacturers around the world are consistently pursuing a local-for-local approach to keep the carbon footprint of battery production as small as possible. SVOLT’s aim is to establish local supply chains that provide the required materials – where available and possible. This reduces the risk of delays and unforeseen incidents for the supply chain. In addition, delivery routes and times to European customers can be reduced, which in turn has a positive impact on the sustainability of electric vehicles.

Simplified approval processes for wind and solar – why not also for energy storage?

So, are all the lights green when it comes to the planned expansion of battery factories in Germany? Well, it could be happening much faster than it is. The difficulties in implementing projects – due to lengthy approval procedures or lawsuits – are paralyzing the progress of the energy transition. In the course of a directive of the European Parliament and the council for the simplification of approval procedures, the European Commission made the following assessment on May 18, 2022: “For some widely used renewable energy technologies, such as wind power and photovoltaics, administrative barriers are now more important than other types of barriers. A prerequisite for accelerating renewable energy projects is therefore the simplification and shortening of authorisation procedures, as outlined in the REPowerEU Communication.” However, there is also an urgent need to allow the production of energy storage systems to benefit from simplified approval and authorization procedures. Many stakeholders in politics and the public are apparently not (yet) aware of their importance for the energy transition.

The future is happening now: Setting the course for a new industrial landscape

Looking at the expansion plans for battery production in Europe, one thing is clear: the decisions regarding where new production and development centers will be located in the coming decades are being made now. The paradigm shift is taking place almost everywhere at the same time – but it will be formative and impactful for a long time going forward. It is a unique opportunity for many areas to establish and position themselves as high-tech regions with an international focus and to become attractive to skilled workers from all over the world in the long term – and certainly a missed opportunity for the regions that do not play a key role in shaping the change now.

There is no question that energy storage systems are urgently needed: they will not only help the transport sector finally meet its climate targets, but they will also produce electricity from renewable sources when many electric cars become part of the Europe-wide smart grid – and thus these energy storage systems will offer the opportunity to become resilient to grid fluctuations. This makes them an important enabler of the energy transition. Traction batteries produced in Europe also form a secure foundation for the future of e-mobility – if their production is not dependent on the vulnerability of global supply chains.